PVC LEAD ACTOR

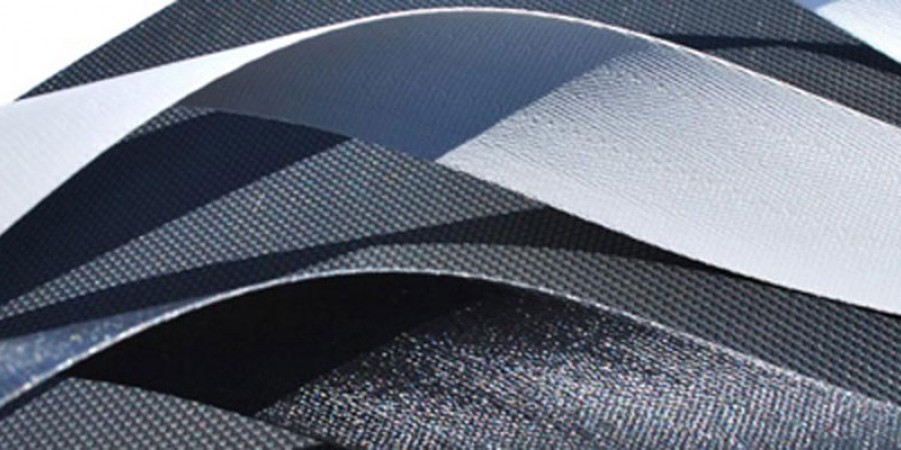

Excellent compromise between costs and benefits, the polyester-PVC coated fabrics are among the most used in the construction sector thanks to their five different weights (Type I-V) which ensure functional mechanical performances to main structural applications. “Of course, PVC does not have only merits – explains Roberto Rescia, Coverhat CEO – but also some limits, such as light transmittance, resistance to dirt and degradation of performances. This limit can be kept under control by appropriate lacquering. Surely its advantages are superior as confirmed by its wide use for some major projects that also require recyclable materials to reduce the impact on the environment.” However, PVCcoated fabrics are not worth one another. In fact, there are different types and the best ones are PTFE glass fabrics, which are considered among the most durable for structural applications (their use is mainly recommended for permanent applications that require a useful life of the product over 25 years). “This is the reason why this material, characterized by excellent resistance to dirt, has been used for high-standing structures such as the Berlin-Brandenburg airport and the Dubai Burj Al Arab Hotel: it is able to face the cost impact of both the material and the corollaries linked to the complexity of processing and subsequent installation”. To make the solution unsuitable for temporary projects, with limited budgets, it is not only the economic component but also the complex geometry that often distinguishes these types of realizations. The possible alternatives always speak the language of PVC but with other variables: silicone coated glass fiber fabrics, expanded PTFE fabrics and Nylon-PU fabrics.

To be continued…