ETFE

The most frequently used film material for load-bearing walls, roofs, or claddings, is the co-polymer Ethyl tetrafluoroethylene (ETFE).

ETFE foils allow a variety of designs which display incomparable lightness and elegance with reference to a unique architectural language. ETFE is highly transparent and unlike other textile membranes it is produced by extrusion and not by weaving. ETFE is one of the most stable chemical compounds which means it is ideal for outdoor applications. Incorporating ETFE into a building’s cladding results in a more efficient and low maintenance structure. Implemented in cladding for botanical gardens, zoo buildings, and swimming pools, ETFE is currently finding its place as an effective alternative to glass in more traditional buildings and in roofing for courtyards, atria, shopping malls and transparent façades. ETFE foils can be manufactured in thicknesses between 50µm and 350µm. For medium or large area projects it is generally used the 250µm in roll widths of approximately 1.50m.

ETFE membranes are 100% recyclable.

Widespread use

The lack of resistance in warp and weft makes the strength of the material lower than the other products and therefore the main use is in the realization of pneumatic cushions. Self-cleaning, weathering resistant and, due to its flexibility, extremely ada

Fritting - Variable shading

Indeed its highly transparency it is also possible to create white or coloured ETFE adding pigments or to coat the foil with patterns in order to control both transmission and reflection obtaining the fulfillment of both sun protection and mirror effects.

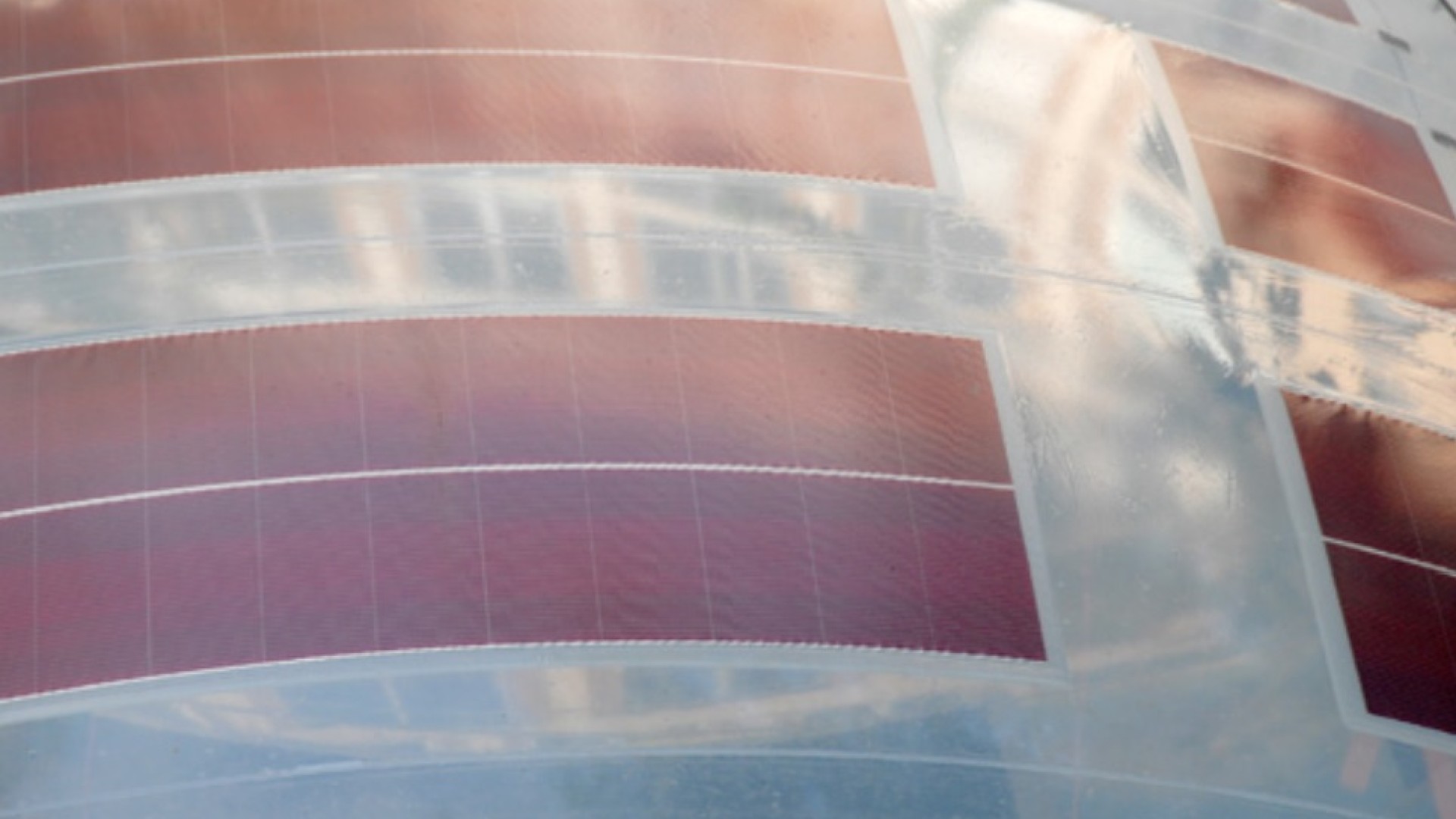

Photovoltaic and LED light integration

Photovoltaic system cells and/or LED lighting can be merge with ETFE system in order to increase the sustainability of the covering and create an astonishing aesthetic efferct.