I'TS Cover Sport Temporary

The airdome born in the war industry and once cleared for commercial use it is used as a valid alternative to traditional structures for covering large spaces, due the simplicity of execution with fast installation and removal procedures for both a short and long duration. The absence supporting structures and the ability to cover large surfaces has decreed the success of airdomes which has undergone considerable evolution over the years and which is currently used permanently for productive activities or in the field of sports activities in latitudes where the climate causes particularly demanding conditions for both cold and heat.

The internal pressure inflates and pre-stretches the membrane, thus allowing it to resist the external loads of the wind and, to a minimum, of the snow; the operating pressure guarantees support and resistance to certain wind pressure values and must be increased in proportion to the wind pressure. The internal pressure and external stress of the dynamic wind load result in significant forces which are transmitted to the anchoring system which must be designed to meet stringent safety requirements. The traction forces are transmitted along the entire base of the airdome to the anchoring system so that the load is not concentrated in the individual attachment points. In addition, the anchoring system seals the membrane along the perimeter, thus avoiding air and pressure drops to outside.

Ventilation is guaranteed in most cases by electric fans, defined as low pressure ventilator, which continuously inject air into the internal volume in order to keep a set overpressure level and which in the various declinations are coupled to the heating system. To meet the safety requirements, the inflation system must operate continuously and be equipped with a backup system capable of replacing the primary unit in case of failure or malfunction. The safety unit, commonly referred to as an emergency generator, is a fan unit capable of assisting the operation of the primary unit in certain weather situations by raising the value of the internal pressure increasing the resistance of the airdome or replacing it completely. The emergency unit can be equipped with an on-board internal combustion engine for moving the fan or there are versions with an auxiliary electricity generator that supplies power to the electric motor that drive the fan.

The entrance and exit in an airdome must occurs through access systems that are able to balance the pressure difference between that of the internal volume and the atmospheric: gates can be pedestrian which are built as tunnel with a double door or a revolving door typically consists of three or four doors that hang on a central shaft and rotate around a vertical axis within a cylindrical enclosure. The vehicle entrances are exclusively built from a tunnel with two sectional doors.

Besides the fundamental components for the airdome, there are safety accessories that makes the use safer, such as emergency exits and secondary accessories such as the lighting system.

Technological evolution found expression in the airdome also: at the beginning in the airdomes no performance ambitions, in terms of energy management, were implemented by passing through the manufacturing of the dome with the double or triple membrane, the insertion of controls electromechanical for pressure management and the use of thermal systems with higher efficiency reaching up to the present day in which the insertion of insulating materials beyond the membranes, the use of electronics for the management of the systems and the LEDs for the 'lighting allow very virtuous levels of efficiency.

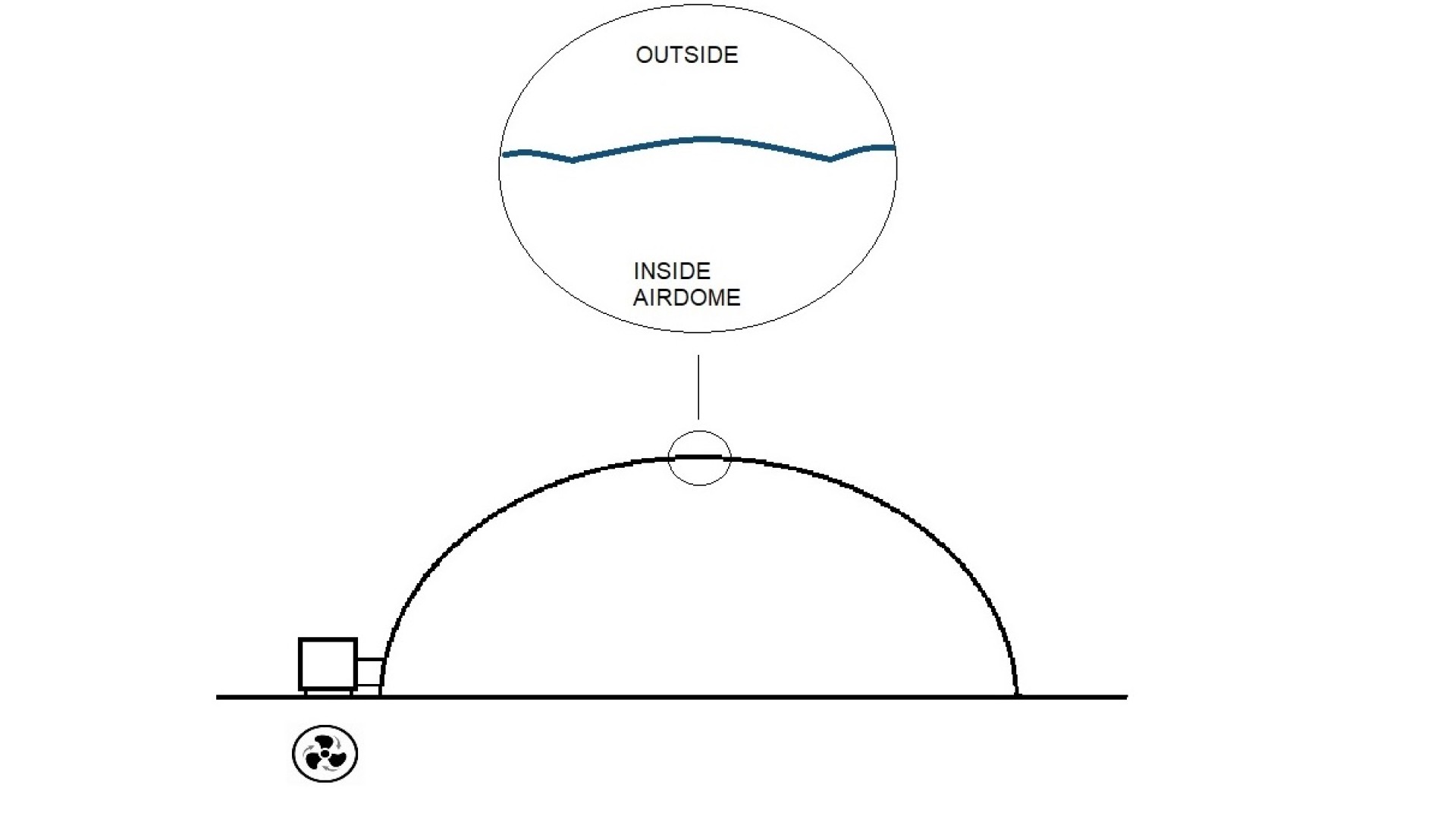

SHIRT Version

Single membrane for covering sport without the need for heating the internal environment. In an era in which sustainability and the green footprint of technologies is an essential mantra, CoverHat acts to give its contribution

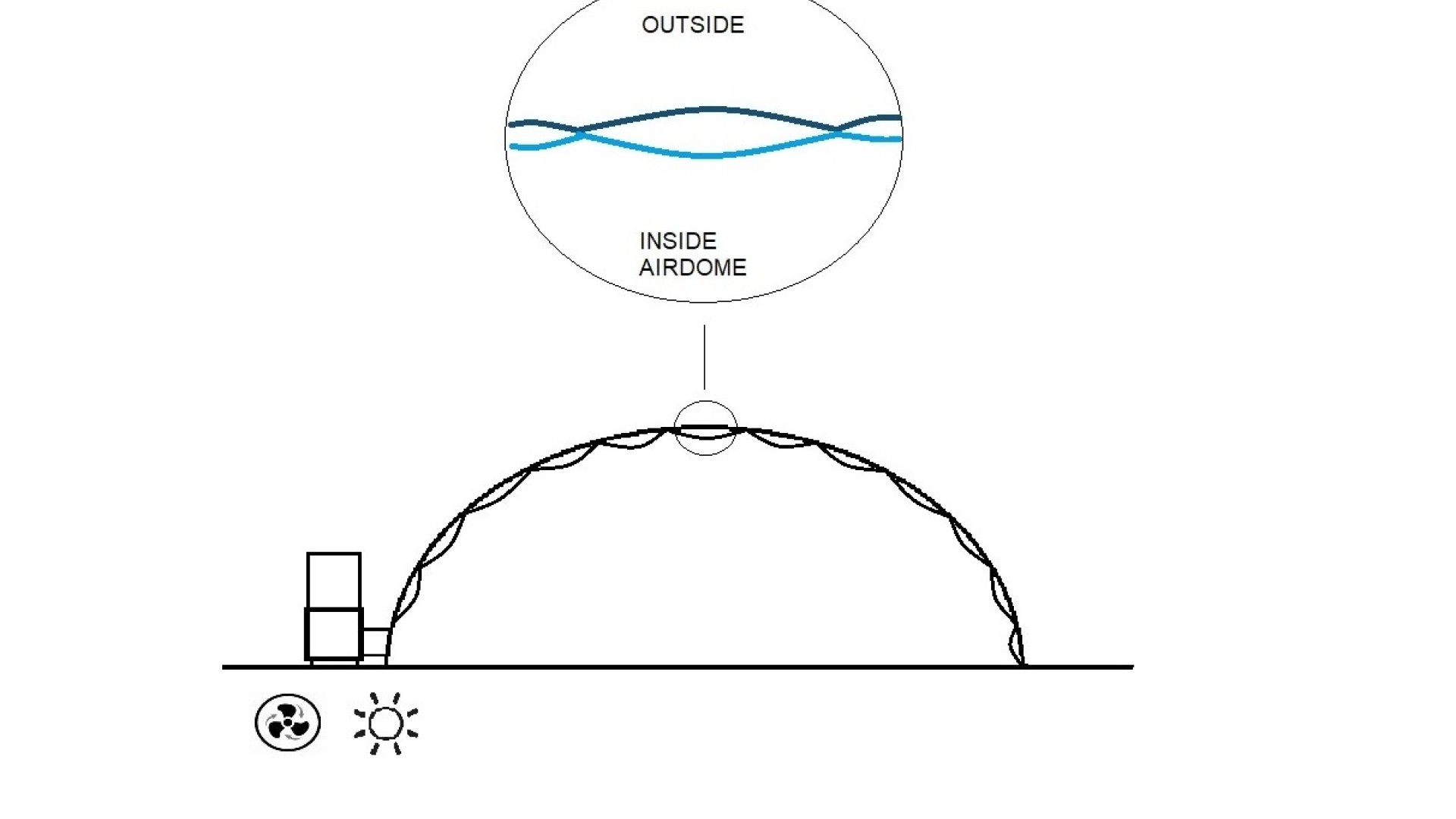

SWEATER Version

Double membrane solution for covering sport and warm the environment for the occupants. The double membrane increases insulating power of the cladding to reduce the thermal power installed and umidity problems.

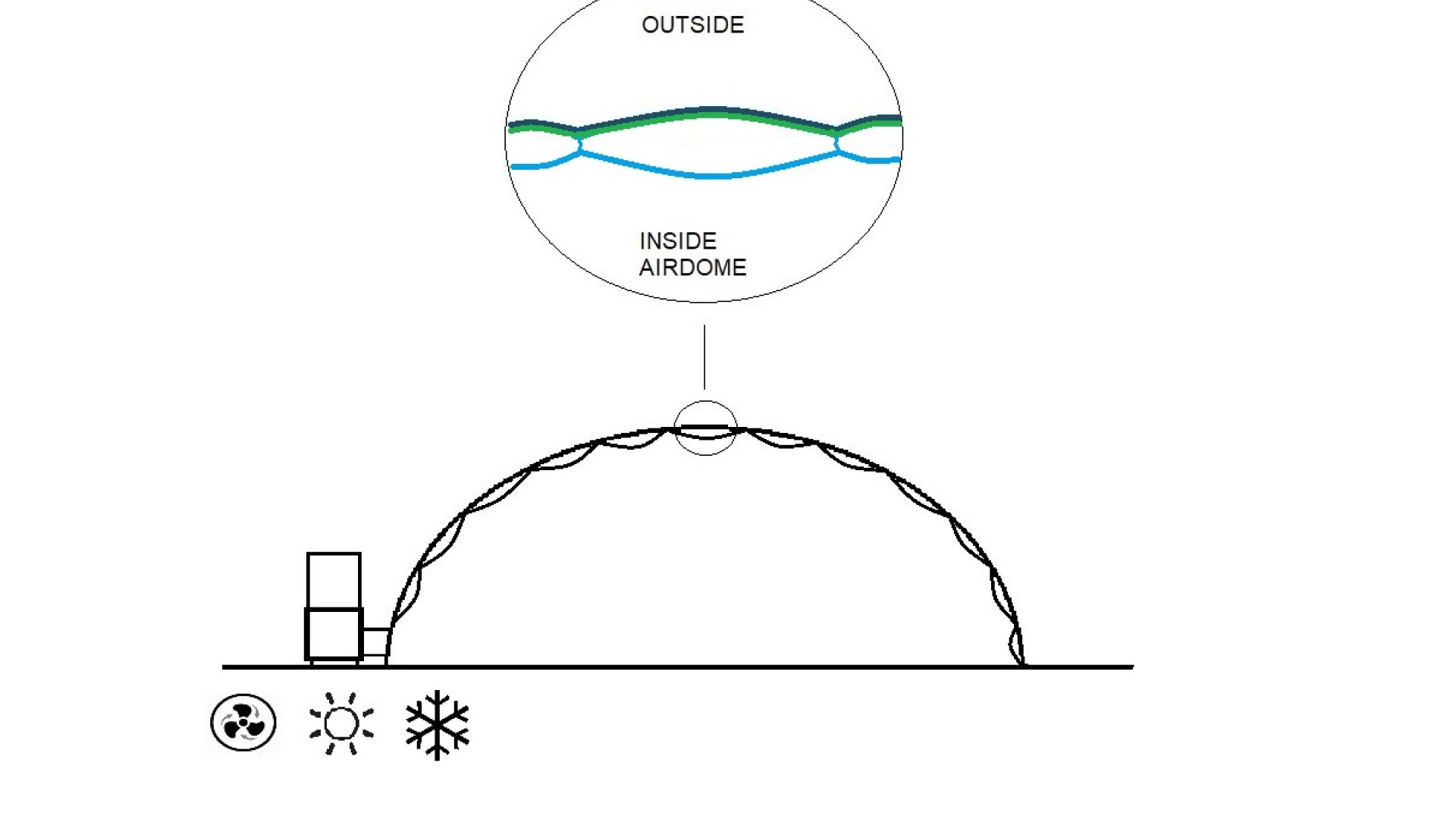

PEARL

Top cover solution for permanent application in a very strong climates, both for extreme cold for which we offer the PEARL WHITE version, and for oppressive heat where we offer the PEARL BLACK version with air conditioning systems.