IT'S Cover Architecture

To use the textile membranes as a covering element, pre-stress and a stabilizing three-dimensional shape are required, which is obtained with a double-curved surface. Both features ensure that the membrane is able to withstand all external loads while transmitting only tensile stresses. The curvature can be anticlastic (membrane stress obtained mechanically as in saddle-shaped structures) o synclastic (membrane stress obtained pneumatically by pumping air into the internal volume such as airdome structures, cushions or inflated beams).

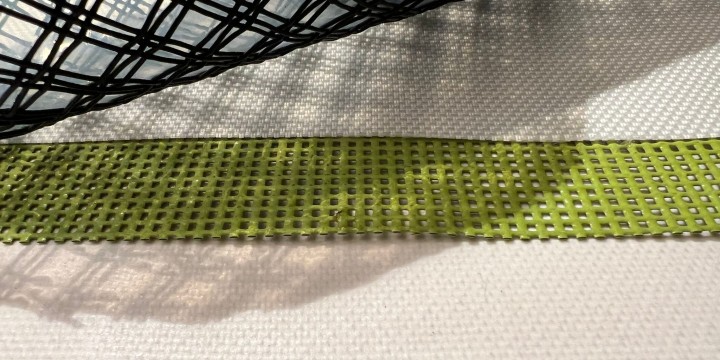

The most common characteristic configuration of a tensile structure is formed by load-bearing elements usually in concrete, wood or metal to make up the primary structure and by a membrane that represents the secondary structure that reacts to the stresses of external loads by deforming, inducing tensile stresses to the primary structure . The transmission of tensile stresses to the primary structure is a very important concept that is always present to keep the membrane's own “shape” even without any external load and is the salient feature that differentiates tensile structures from traditional structures. Contrary to traditional structures, the “shape” of a textile membrane must be found in the first phase of the project and represents a balance surface between the geometry of the edges and the level of tension in the membrane that satisfies aesthetic, structural and maintenance requirements.

The following phases in the design process of tensile structures are the static analysis of the system to size the various elements and the study of the cutting pattern for the preparation of the membrane slits for the subsequent manufacturing of the membranes to form the covering envelope. Another fundamental aspect for the use of membranes is the compensation coefficient which represents a reduction of the geometrically designed dimensions in order to obtain the design pre-stress once the membrane is elongated during installation. The goal of the cutting pattern and the skill of a manufacturing company is to obtain the theoretical form at the end of the installation while keeping the design pre-stress.

The design activities of a tensile structure can be schematized by separating them into well-defined activities with a preparatory course that figure out the entire process, but it must not deceive, because if it is true that the previous activities are necessary to carry out the subsequent ones, the entire cycle is the sum of an iterative process implemented until an acceptable mathematical approximation is reached.