Polyester PVC

Polyester coated PVC fabric is the most commonly used fabric in architecture as it offers the best ratio among cost, performance and durability.

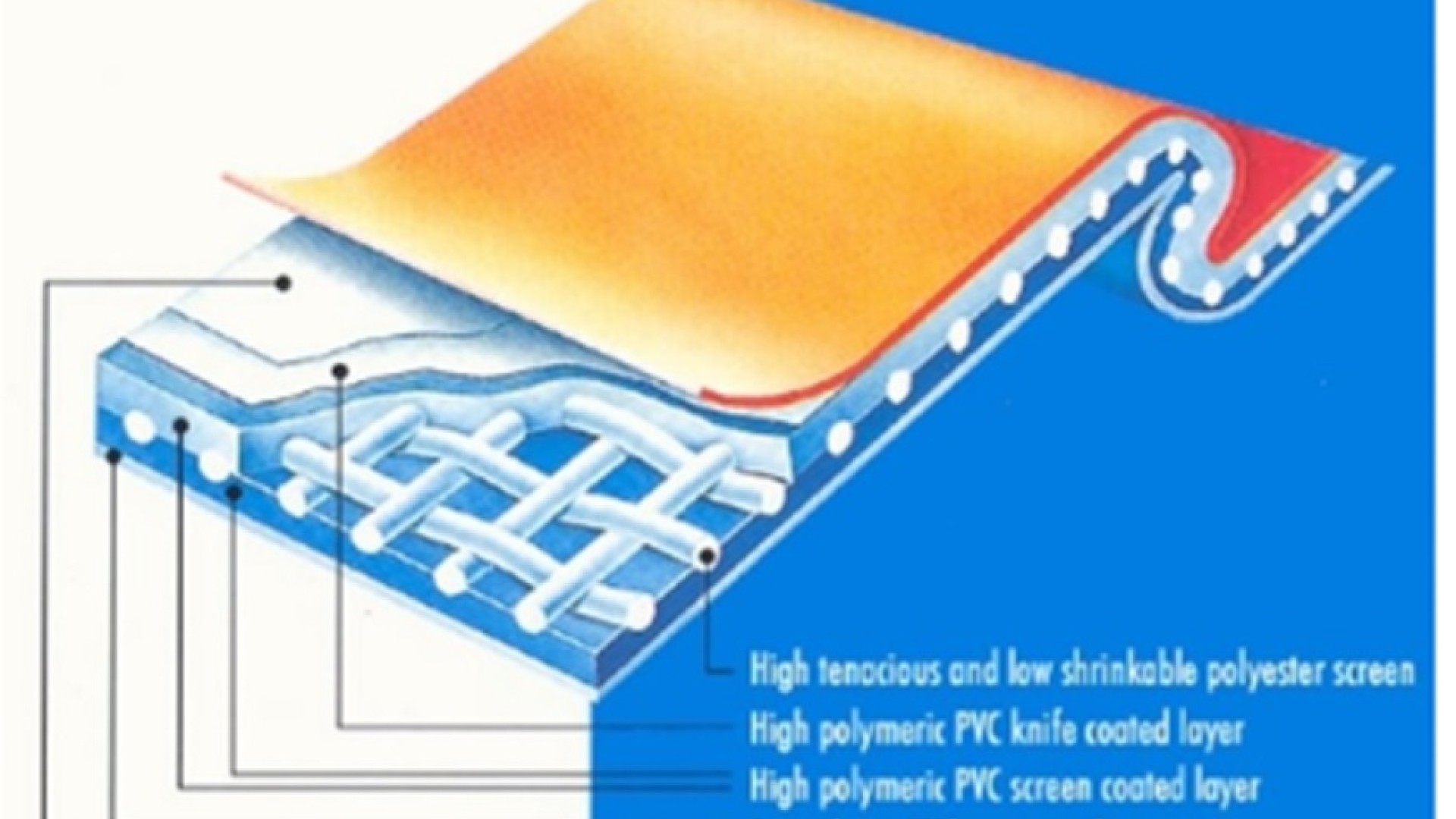

The coating of a technical fabric, unlike an industrial fabric, is obtained by coating the polyester base fabric with PVC and other products used to improve their performance; those are additives such as dyes, stabilizers, plasticizers, flame retardants and anti-mildew.

These highly functional fabrics come in a wide range of colours, light transmissions and tensile strengths. Open-mesh and opaque fabrics are becoming increasingly popular for semi-transparent fabric façade applications

In addition to permanent structures, mobile membrane constructions are feasible as the polyester fabric is tear-resistant.

Depending on usage lifespan can be from 15 to 20 years.

This material meets the requirements of the fire classification B1 (flame resistant)

Multi-layered membrane structures can be provided with excellent thermal properties either through the entrapment of air, or by the insertion of insulating materials that meet the requirements of high thermal insulation building shells.

Suitable for use in all weather conditions

Main structure

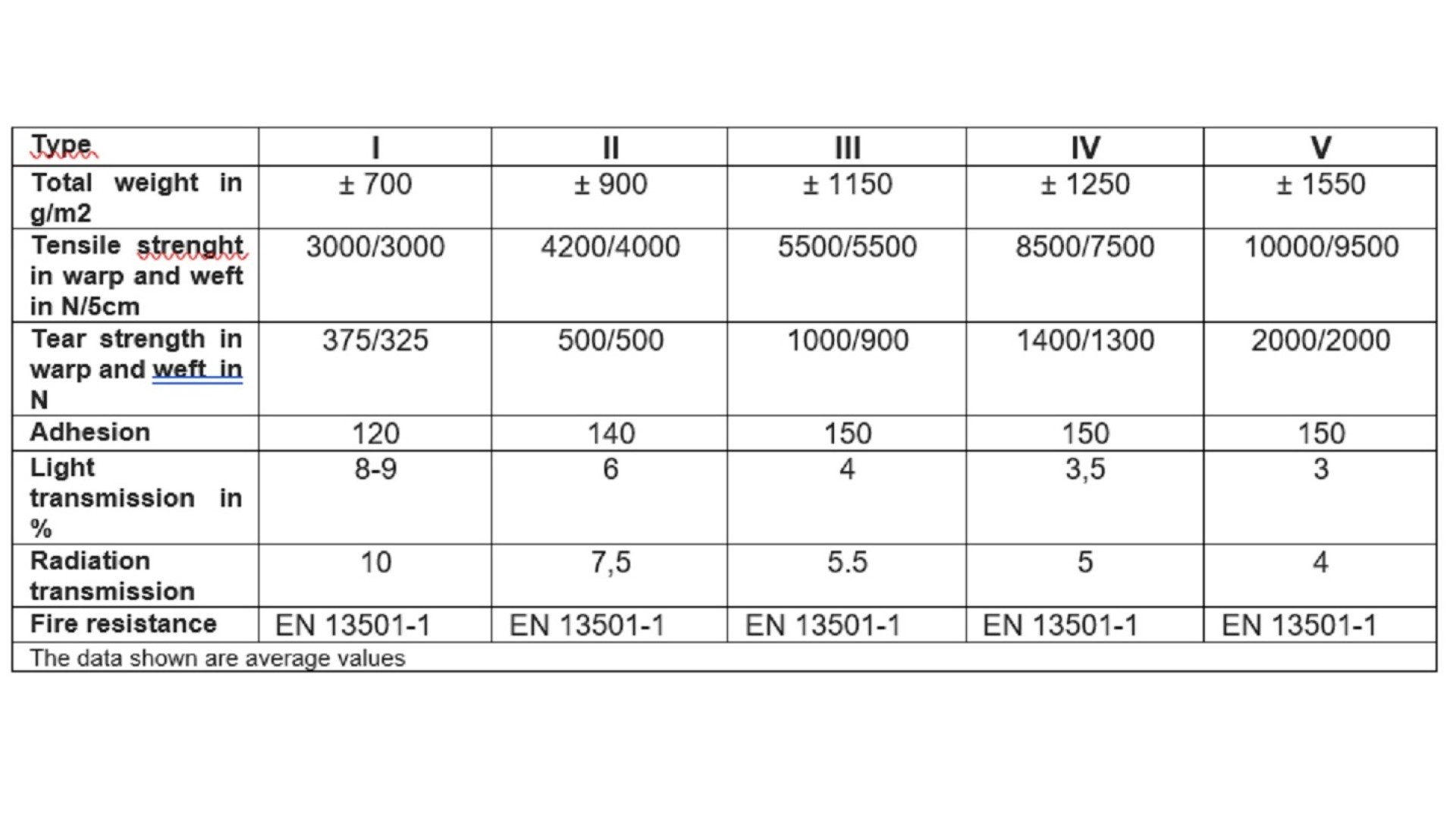

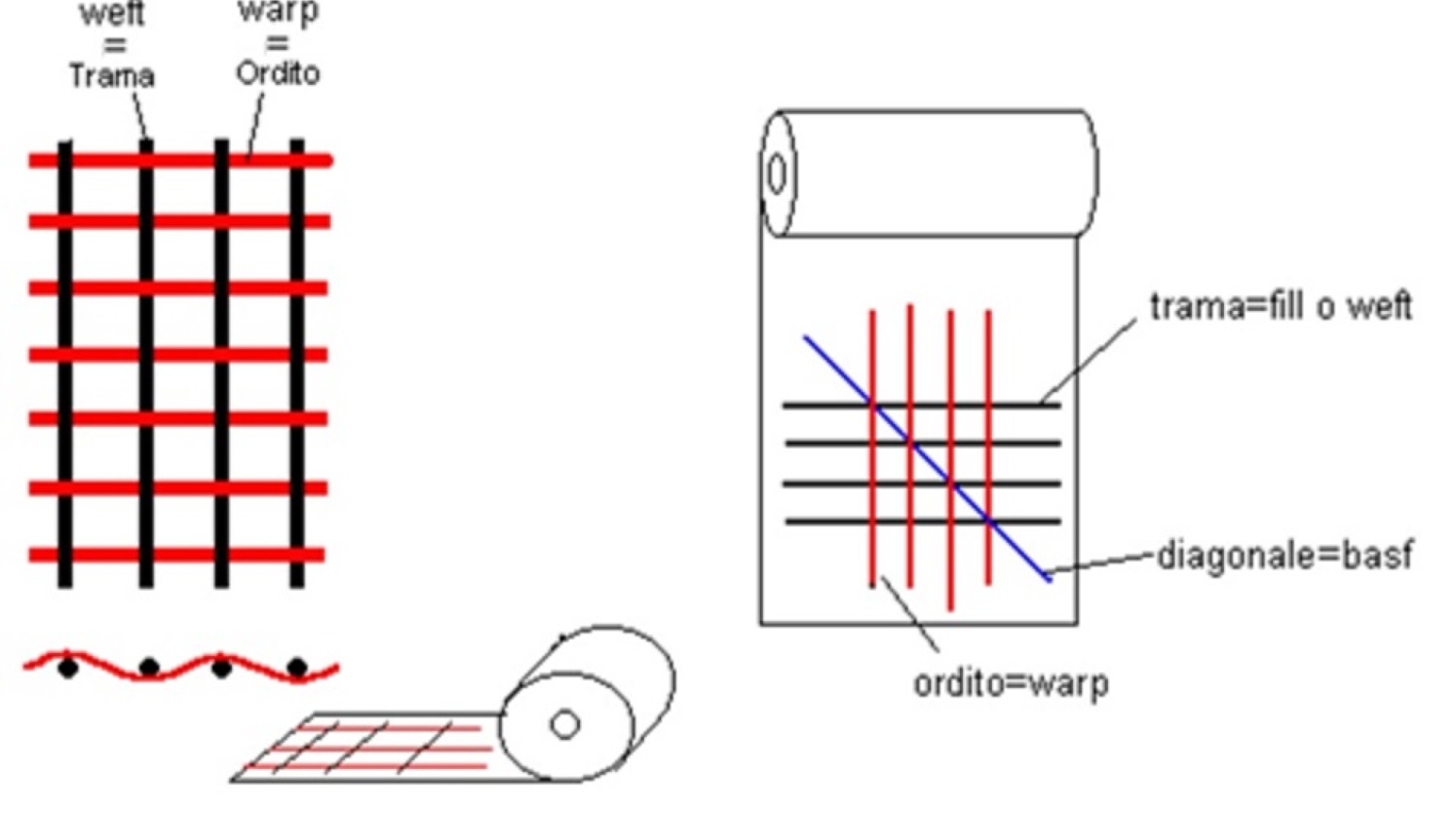

This high-strength membrane material has been in use for more than 40 years; it is produced in 6 types (from 0 to V). Each type is characterized by a different weight per square meter and by resistance values in warp and weft which increase accordingly.

Coating

Besides there is an additional lacquering with PVDF (polyvinylidene fluoride) that reducesthe yellowing caused by UV rays and the vulnerability to air pollutants by increasing the durability of brightness and white.

Datasheet

Suitable for sewing or high frequency welding